- Galaxycore GC5025, 5MP, 1.12um pixel, integrated ISP - $0.53

- Galaxycore CG032A, VGA, integrated ISP - $0.15

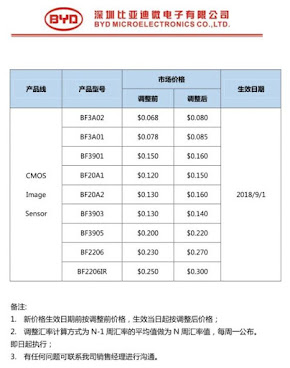

- BYD BF2206, 2MP - $0.23

- BYD BF3903, VGA, integrated ISP - $0.15

- BYD BF3A02, QVGA - $0.068

Once we are talking about Galaxycore, the company has been requested to compare its sensors performance with others on the market while preparing its IPO. Galaxycore claims that it's similar to the market leaders.

Brigates has changed its name to Ruixin Microelectronics and prepares an IPO at the valuation of 1B yuan. The company has lost the money in 2017-208, then turned a profit in 2019:

"In the past three years, Ruixin Micro's revenue was 52.197 million yuan, 146 million yuan and 253 million yuan respectively. In 2017 and 2018, net losses were 15.1624 million yuan and 279 million yuan respectively. In 2019, it turned losses into profits, with net profit of 52.117 million yuan. Based on this, Ruixinwei finally chose a listing standard with an estimated market value of not less than 1 billion yuan, a positive net profit in the most recent year, and an operating income of not less than 100 million yuan."

Meanwhile, Omnivision's mother company Will Semi share price rose by 20x since its IPO 3 years ago:

Mind-boggling for us old-timers. But also the realization of the promise of low-cost CMOS image sensors.

ReplyDeleteIn 1994, the cost of a CCD was about $50/Mpixel (10 um pitch). Also in 1994, when still at JPL, we suggested CMOS image sensors could achieve 5x reduction to $10/Mpixel (10 um pitch).* At a 1um pitch that might be 100x smaller so $0.10/Mpixel.

This is close to the prices shown. So it should not be so mind-boggling, yet it is.

*http://ericfossum.com/Publications/Papers/Dev%20of%20CMOS%20active%20pixel%20image%20sensors%20for%20low%20cost%20commercial%20apps.pdf

Well, the Moore's law does help in scaling the cost per MPx, especially if pixels are possible to be made smaller.

DeleteI would be interested in your historical view on other factors - e.g. how had the price changed - for a 1mm square of active area (or die area), in a typical, image sensor capable, silicon process? Does it vary for a bulk-consumer process vs. one used for a high-end sensitive/low noise parts?

And secondly, does the fill-factor improve, or is it about the same ratio during the few decades? While V-nand did revolutionalize storage components, I assume we got only the BSI and multi-die stacking, to help in this aspect, right?

If you take global shutter sensors for industrial applications, the price level is still at about 50$ per MP today.

DeleteBTW, for a CCD all you are buying is/was the pixel array and the SF output amplifier. Timing generator, biasing, driver ICs, and signal conditioning and ADC chip(s), and ISP-type chips were all extra costs.

Delete@Daniel - I don't really track wafer prices much, but my sense is that the cost per wafer/mm^2 has not changed too dramatically, even as the number of mask layers grows and the technology node shrinks. Maybe it has gone up about 5X. I don't think high end devices cost a lot more to make than consumer devices, unless there are expensive extra process steps (e.g. stitching). However wafer and die pricing is very elastic at all stages of the supply chain. Buy a lot and the price drops significantly. So high parts naturally cost much more under this market elasticity. Fill factor of course made a dramatic jump with BSI as a mainstream process. FSI photon management was impressive too, by about the same time, so effective fill factors were high for FSI but with some complicated light-pipe construction layers. Remember that BSI was driven by pixel shrink and loss of valuable light collection area on the front-side.

Impressive!. as posted here: http://image-sensors-world.blogspot.com/2020/09/assorted-news-sense-photonics-mipi.html, the estimation for the price of a wafer (I suppose 300mm?) in the 90nm node is about 1700$, lets assume this matches the cost for Galaxycore to produce a 5MP wafer. There is a calculator for how many dies you get from 1 wafer for example here: https://caly-technologies.com/die-yield-calculator/. 5MP is about 2500x2000 pixel, at 1.12um about 3-2,5mm, lets say the dies are 4x3mm, you get about 5000 dies per wafer, about 0.34$ cost per die. If this was true... they would make about 0.20$ per die or about 1000$ per wafer (before covering costs for packaging, testing, shipment etc.).

ReplyDeleteAs mentioned above, price level for industrial global shutter sensors is in the 50$/MP range. Pixel size is in the 3-4u range. A popular sensor in this class has about 2500x2000 3.45u Pixels. Just for the magnitude, lets assume a die size of 10x8mm, so about 600 dies per 12" wafer. They get sold for about 250$ each - 150k per Wafer. A camera manufacturer adds a housing and power supply and sells industrial cameras for 200/MP. This is a business with impressive margins - if you are able to deliver the technology (I'm still impressed by how much industrial camera manufacturers are able to charge for the little they add to a image sensor. All the technical complexity is in the sensor. Adding housing with cmount interface, power supply and communication is trivial compared to the sensor. Nevertheless 80% of the cost is in the camera, not the sensor...

DeleteDoes it exist price segments between the low cost one or the very high-end reported here?

ReplyDeleteAre you sure these prices also apply to Sony highest Mpixel made in volume for mobile?

The lowest cost sensor pricing may consider the cost of innovation fully amortized (and sometime following investment/effort from companies outside China...)

China is often fighting on price as a way to ensure business against competitors.

Some may remember the bloody war of DVD players, where the price race happened between Chinese manufacturers, leading to sell too cheap and then killing manufacturers and suppliers, while the market was still active (ie before Blue-ray or support-free technologies).

If the 'market hand', in theory, leads to benefit to end customers, price war may also impact innovation and set monopoly for the last/few remaining suppliers.

But I am not sure if this price fight may impact innovation in imaging sensor semiconductor ?

"industrial global shutter sensors"

Delete