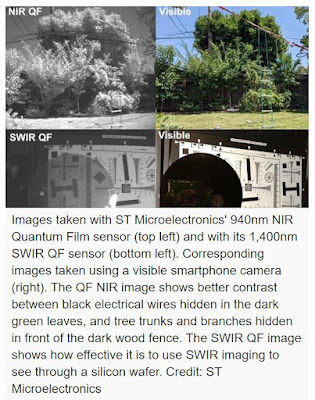

Imaging & Machine Vision Europe publishes an article about ST QD sensor presentation at IEDM 2021:

"The company demonstrated a 1.62µm pixel pitch global shutter SWIR sensor, with a quantum efficiency of 60 per cent and a shutter efficiency of 99.98 per cent at 1,400nm.

The devices were manufactured on 300mm wafers, so suitable for high-volume production at a relatively low cost.

Speaking to Imaging and Machine Vision Europe, Jonathan Steckel, director of advanced technology intelligence in imaging at ST Microelectronics, and lead author of the paper, said that the cost of the sensor could be down in the single-dollar region, similar to what would be paid for a silicon imager.

The ST work though shows commitment to high-volume production, and could open up SWIR imaging for consumer electronic devices and other larger volume applications.

‘The potential of the technology is that you can essentially do SWIR imaging at silicon cost,’ Steckel said.

The disadvantage of CQD technology for shortwave infrared is that the quantum efficiency is lower than InGaAs sensors. Steckel said that ST’s quantum dot SWIR image sensor is not a huge leap in performance compared to CQD sensors from other suppliers, but that ST is going to make it available at a significant scale and with the reliability that consumer electronic customers demand.

In academia, Professor Edward Sargent at the University of Toronto has reported 80 per cent quantum efficiency of a CQD photodetector at 1,550nm.

‘In industry, in the next couple of years, we’ll probably also be able to develop our technology to hit higher quantum efficiencies, upwards of 70-80 per cent,’ Steckel said. ‘Then it would create more of a value-add, and more of a gap between what silicon can do versus what CQD can do in the NIR, and also close the gap between what InGaAs can do versus CQD technology in the SWIR.’

IMVE also publishes Paweł Malinowski, program manager at Imec, response to ST IEDM presentation:

"Yesterday, at the 67th International Electron Devices Meeting (IEDM), the tone-setting event for the semiconductor industry, ST Microelectronics announced QD image sensors. The 1.62µm pixel pitch sets a new record, and the external quantum efficiency of 60 per cent at 1,400nm inches ever closer to the values found in the incumbent technologies.

The most exciting feature is that these results come from chips fabricated using a 300mm wafer platform – this means that the QD technology has made significant strides in making it ready to manufacture. Upscaling to a wafer-level process promises extraordinary throughput and thus cost evolution. New sensor products based on this process will disrupt the market further, and act as a critical enabler for SWIR imaging in applications that never considered it before, including consumer products.

Looking forward, there are still technological challenges to address. Moving away from lead sulphide-based QDs to lead-free material systems will encourage more players to accept this type of sensor. Improving deposition throughput of the quantum dot layers by going to one-step coating – instead of the standard layer-by-layer coating used currently to achieve the desired final thickness of the absorber – will significantly increase the takt time in volume production.

Moreover, thorough investigation of reliability metrics according to industry standards will set further iterations of QD improvement to optimise long-term stability, and enable even the most harsh applications such as those demanded by the automotive sector."

"Quantum dot technology offers a more attractive solution. In comparison with InGaAs or Ge, colloidal quantum dots require a much simpler fabrication process. Due to inexpensive deposition techniques, QDs are easily integrable with conventional silicon integrated circuits. As a result, quantum dot technology makes it possible to mass produce VIS-SWIR cameras. This, in turn, reduces the price per VIS-SWIR sensor by 3-10x times potentially, making them much affordable for end users.

There are several organisations that have taken this opportunity and have started applying quantum dots in VIS-SWIR cameras. Emberion is one of the pioneers in commercialisation of quantum-dot based VIS-SWIR cameras. In 2021, they introduced to the market a new product of VIS-SWIR camera based on their in house designed CMOS ROIC – Emberion VS20."

No comments:

Post a Comment

All comments are moderated to avoid spam and personal attacks.