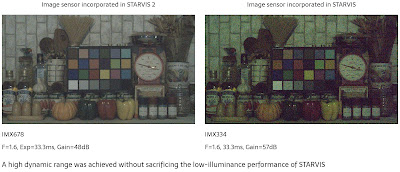

"As the importance of image sensors for security cameras which monitor spaces is growing day by day, the characteristics required of them are also becoming more advanced. Fulfilling all of these requirements, which include low-illuminance performance to allow targets to be discerned even in dark locations, a high dynamic range for face recognition even against a light source such as in entranceways, and performance capable of recording images of moving targets accurately without causing blur or color tints, was a task at a level impossible to accomplish just with improvements to conventional sensors. That is why STARVIS 2 was developed. By redesigning the structure of its image sensor from the ground up, it has successfully implemented characteristics unmatched by any other."

Sony publishes an interview with STARVIS 2 developers:

Shimizu:It was triggered by requests from our customers. Although STARVIS had achieved greater low-illuminance sensitivity and improved image quality performance, there were also separate requests to expand its dynamic range so that faces could be accurately recognized even in situations such as entranceways, where the exterior is bright and shooting images against that light source causes faces to become dark and shadowed. Development on STARVIS 2 began to answer these requests.

Shirahama:Normally, we move on to commercialization only after a product’s technology is in place, but since both proceeded simultaneously in this case, we were required to execute development and testing in extremely short cycles. We had no choice but to move forward while resolving each issue one at a time. Because of these conditions, the first prototype was full of problems and was completed in a state that was entirely unacceptable for commercialization.

However, since there was no leeway in the commercialization schedule, delays were not something that could be allowed easily, so the question of how to move the overall project forward while staying aware of its issues was very important. Even when we thought “It’s no use anymore,” we kept an eye on the schedule while resolving each problem, and took one step ahead at a time. And as we did so, our thoughts of “It’s no use anymore” gradually changed more and more into feelings of “Maybe it will work!” Even though the team for this project consisted of members working together for the first time, they possessed the capabilities to solve issues and the flexibility to skillfully move the project forward even under its strict schedule. I began to think “This just may be an incredible team” and working with the team became more and more enjoyable. One of the unique experiences that arose during this project was that as it went forward, the trust we felt toward our team grew and grew.

Kawamura:As our development policy, we are constantly making product improvements while maintaining the strengths of the products. This time, in order to address the issue of expanding the dynamic range, there was a need to increase the saturation of the photodiode. Therefore, instead of attaching the photodiode to a conventional silicon surface, we developed a structure which accumulated electric charge in the vertical direction within the silicon.

At the same time, we also introduced new technology for a high dynamic range feature.

We had to proceed with the development of these two new structures that had not yet been established while staying within the schedule for commercialization, so it was a challenge under an extremely tight development period. As Shirahama-san mentioned earlier, there were problems with charge transfer in the initial prototype and it was full of issues, so we were not able to even sufficiently evaluate them.

Iwabuchi:This vertical-structure photodiode had not yet been applied to image sensors, so it was a technology with high risks regarding mass production. Still, we desperately needed a form of breakthrough technology to achieve a wider dynamic range, so since there was a section for prototypes on the development line at Atsugi TEC, we started by trying it out there. We proceeded step-by-step starting from verifying its principles as we marked each development milestone. The commercialization schedule this time had been formulated under the assumption that all parts of technological development would proceed smoothly. As we were faced with successive issues from the very start that did not go as planned, we were continually walking a tightrope to figure out how we could somehow maintain the development schedule.

Iwabuchi:To expand the dynamic range, we had to increase the saturation signal while also suppressing noise.

The new vertical structure adopted this time was an innovative structure that could increase the saturation signal amount, but we faced tremendously difficult struggles to optimize the process conditions so that those increased signals could be transmitted reliably.

Regarding the other matter of noise suppression, since both the structure and process were new, we were thoroughly aware of the possibility that the dark characteristics, which were the cause of noise, might become worse.

In order to simultaneously resolve the two issues of increasing the saturation capacity while suppressing noise, we implemented various measures such as reviewing the pixel layout and process conditions, and finally succeeded in developing characteristics to obtain image quality that would fulfill the requests of our customers.

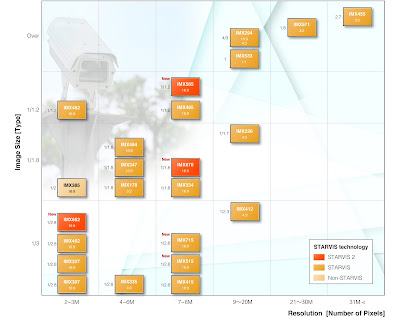

Kawamura:In this project, we made a change to a new pixel structure, but I believe it is still just the beginning. Changing the photodiode to a vertical configuration to make it possible to increase the saturation capacity for greater depth has an enormous amount of hidden potential. I believe it will become essential in the security field to improve image recognition rates, so we intend to further enhance our pixel characteristics such as infrared sensitivity and high dynamic range while also miniaturizing pixels, to make our range of image sensor applications wider than ever before.

Iwabuchi:I believe that Sony’s strengths lie in its ability to carry out advanced development of image sensors with unequaled characteristics that use processes which cannot be copied by competitors, like STARVIS 2. Sony has an atmosphere which encourages new internal challenges, and its engineers in each field are full of motivation to try new things. I hope that we will be able to fully apply the advantages of this environment, to continue to develop revolutionary image sensors distinctive to Sony which are the first of their kind in the world.

I wonder why they have not yet applyed STARVIS to mobile phones cameras and consumers cameras? Smartphones become blind in a slightest darkness, their cameras are lacking in sensitivity badly. Down with megapixel race! Let them embed at least one highly-sensitive 2-3MP STARVIS sensor into at least one model of cameraphones.

ReplyDeleteThey are too big for that they are more for security

DeleteSo then their smartphone would be thicker - for a good reason that is wanted by purchasers. Imbed the STARVIS sensor in a phablet or tablet. There are smartphone apps, such as "Alfred" (and "www.AlternativesTo", that provide home surveillance. There are also smartphone apps that provide the functionality of dashcams/dashboard cameras.

Delete