Images defocus over wide temperature range is a challenge in many applications. poLight's TLens technology behaves the opposite of plastic lenses over temperature, so just adding it to the optics stack addresses this issue.

A whitepaper is available here: [link]

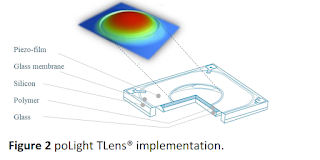

Abstract: poLight ASA is the owner of and has developed the TLens products family as well as other patented micro-opto-electro-mechanical systems (MOEMS) technologies. TLens is a focusable tunable optics device based on lead zirconium titanate (PZT) microelectromechanical systems (MEMS) technology and a novel optical polymer material. The advantages of the TLens have already been demonstrated in multiple products launched on the market since 2020. Compactness, low power consumption, and fast speed are clear differentiators in comparison with incumbent voice coil motor (VCM) technology, thanks to the patented MEMS architecture. In addition, the use of TLens in the simple manner by adding it onto a fixed focus lens camera, or inserting the TLens inside the lens stack, enables stable focusing over an extended operating range. It has been demonstrated that the TLens passively compensates the thermal defocus of the plastic lens stack/camera structure. The fixed focus plastic lens stack cameras, usually used in consumer devices, typically exhibits a thermal defocus of a few diopters over the operating temperature range. Results of simulations as well as experimental data are presented together with a principal athermal lens design using TLens in only a passive manner (without the use of its electro-tunablity) while the electro-tunability can be used to additionally secure an extended depth of focus with further enhanced image quality.

Achieve athermalization through a passive Tlens is much more complicated than using one or two molded or polished glass elements, and not even cheaper. Besides, module XY sizes will increase with a Tlens. Not mentioning some limitations of Tlens in the lens design, for example clear aperture. So using a Tlens only in passive mode to achieve athermalization is not the best idea in terms of processing and packaging, athermalization or module miniaturization.

ReplyDeleteGreetings from the poLight team,

ReplyDeleteDear commentator, while we concur with your comments on the complexity of creating a thermal solution, per our paper, athermalisation benefits of TLens® is that it thermal/optically behaves the opposite of the plastic or hybrid lenses, and it has been proven to work in commercial camera module products already launched on the market.

Also, in our experience, camera module XY size does not increase but is minimized when TLens® is used as compared with other AF actuator based modules (in fact, module miniaturization is one of TLens®'s strengths).

We will be happy to discuss further, please feel free to contact us directly at info@polight.com. Thank you.